Riley Cox, Fibers, 2023

Project Overview

For this work I was interested in Bacterial cellulose as a permeable material that could possibly be used as a fabric. I was inspired by the research of Mary Tsang who is looking to create open source methods of obtaining hormones at home. I built a filter following the process she developed to extract estrogen from urine and soaked my dried bacterial cellulose in the hormones I extracted from my own body. This project is imagining a speculative future where we could grow our own clothes and in doing imbed our hormones to share with each-other in the same way we share clothes. I am interested textiles as a second skin, questioning where the body stops and starts.

Process

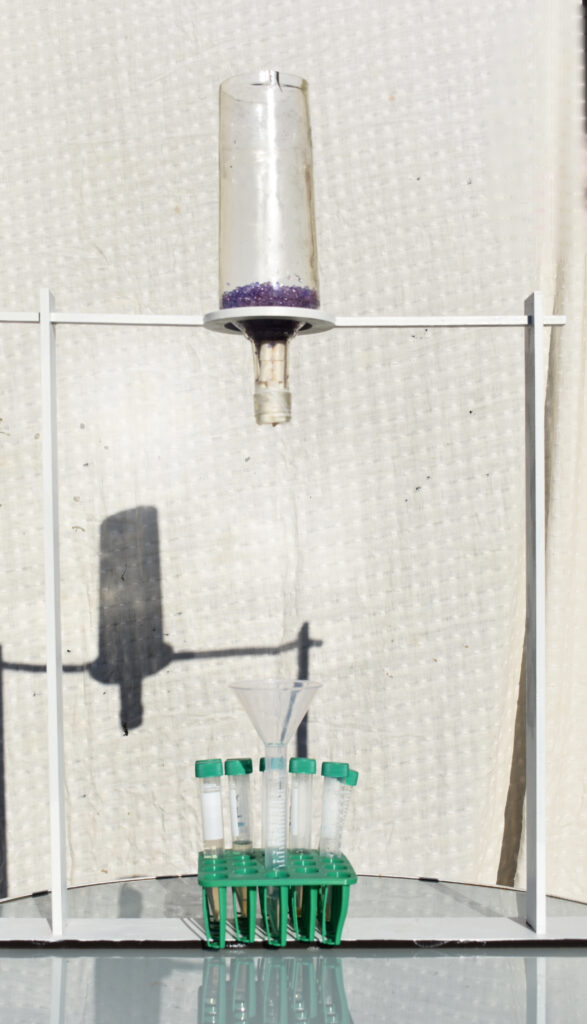

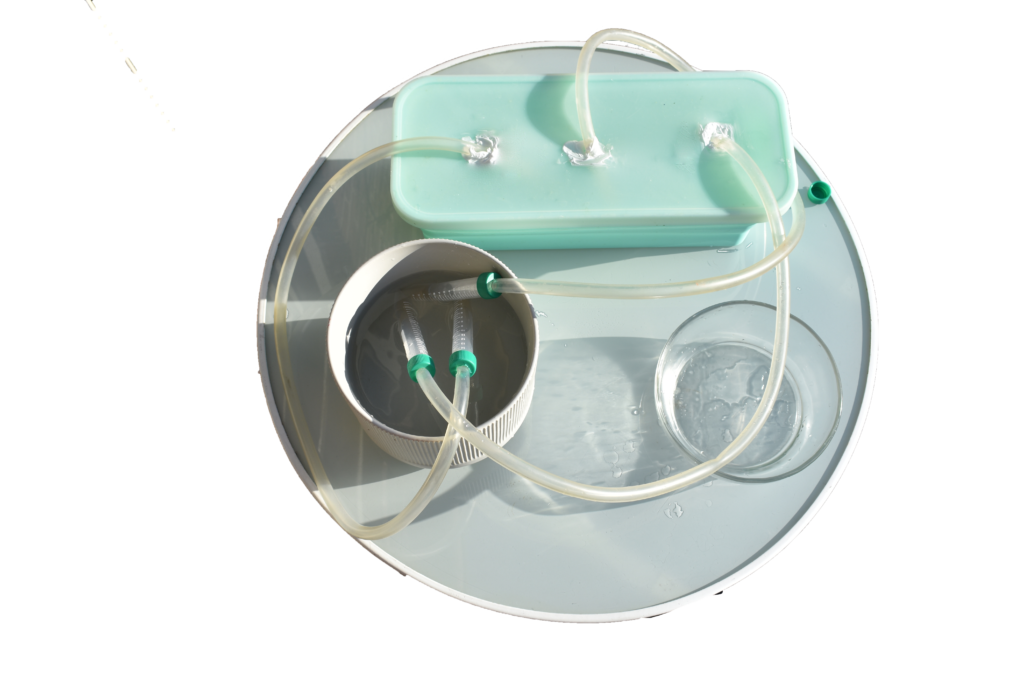

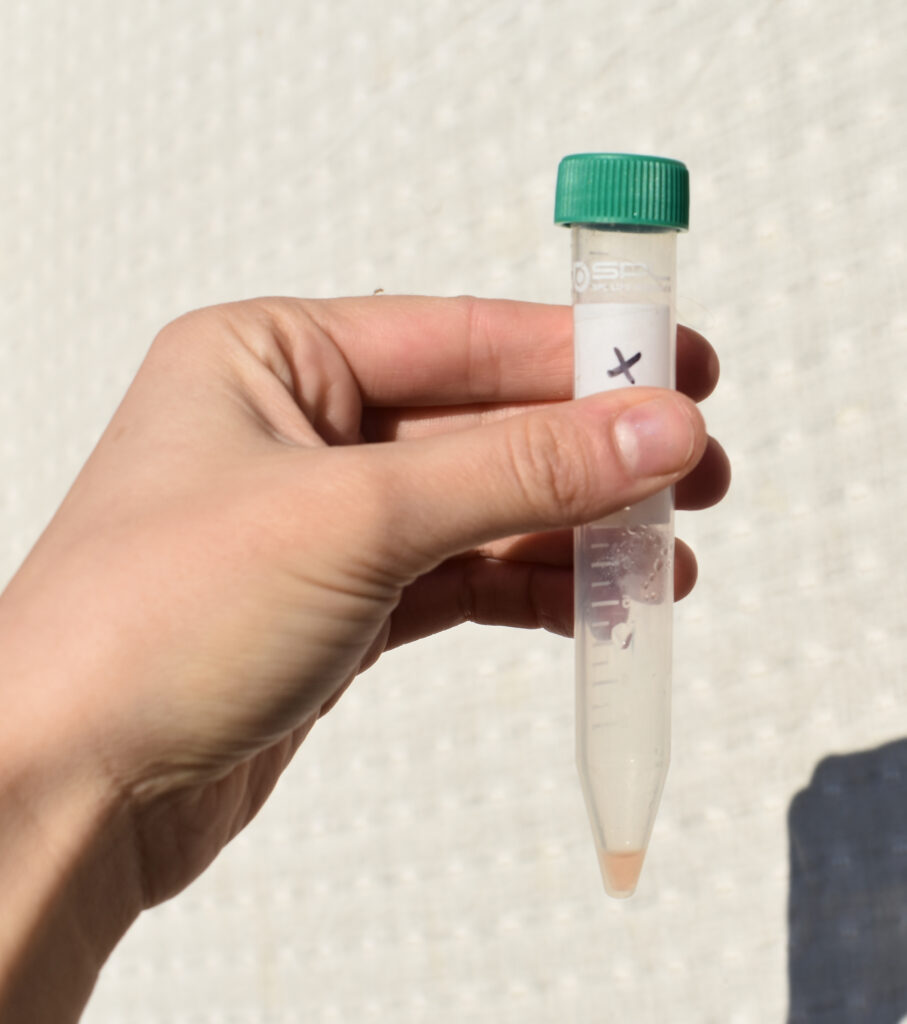

I started this by building a similar filter to one Mary Tsang developed at the MIT media lab. This involved cutting glass bottles and laser cutting a wooden base to hold the glass structure. The bottle is then filled with color indicating silica beads and the neck is stuffed with cigarette filters (a cheap alternative to lab grade filters for this process). Water and Methanol is poured through the filter to condition it before adding urine. Once the urine is poured through, Steroids in the urine should theoretically remain within the silica beads. A final pass of methanol is pored through and collected in test tubes. The methanol needs to be evaporated to isolate the hormones so I built a diy device by hooking silicone tubes to the top of the test tubes. The silicon tubes connected to a larger silicon box for the evaporated methanol to travel into. I heated the test tubes in a double broiler until the methanol had evaporated out. Once reduced, I soaked my dried pellicles in the remaining hormone solution. I then cut these into patches to sew into a shirt.

To make the shirt out of bio plastic, I used a recipe of 500 ml of water, 16 g of gelatin, 27 g of vegetable glycerin and 60 ml of dish soap whisked in once reduced over heat. I laser cut the pattern out of wood and compressed a layer of thin, non stick plastic between a wooden board and the board with the pattern cut out. Because the edges of the mold are wood. The bioplastic will only shrink in the z axis because it sticks to the sides. After drying for about a week, a thin sheet of foam bioplastic is able to be cut out of the mold with a similar feel to latex.