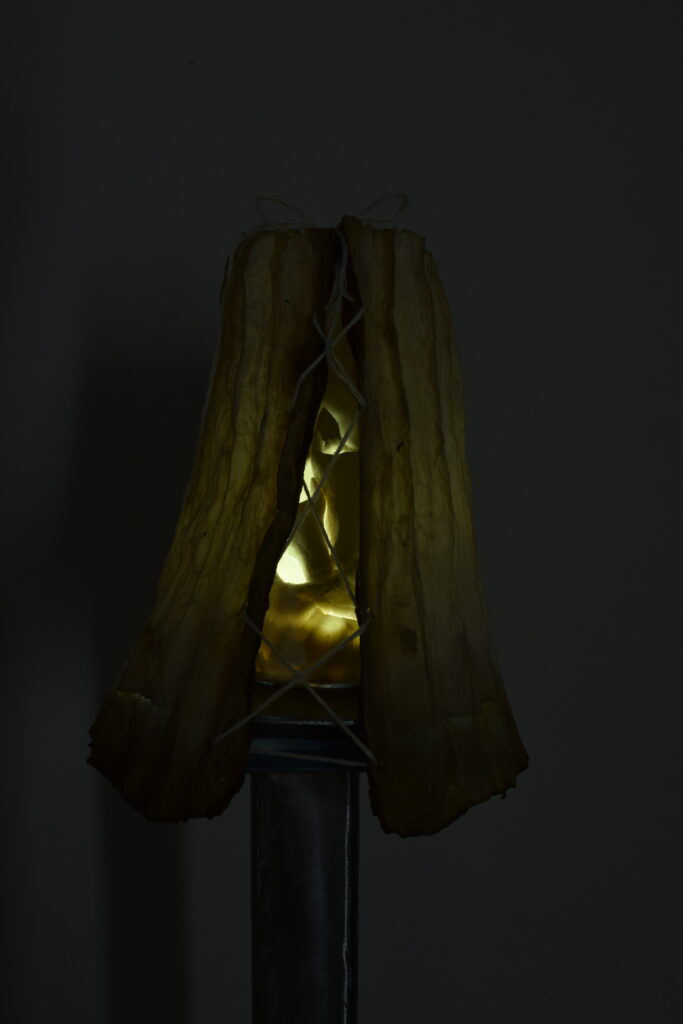

Sarah Becker, Interdisciplinary Sculpture, 2022

Project Overview

Mom, I love you.

Bacterial Cellulose, Rose, Steel, Miami Snow (Porcelain), and light

2022

I Miami Snow, a porcelain recipe that reads as follows:

25% GROLLEG

25% NZL

25% Silica (Flint)

22% Nepheline Syenite

3% Veegum T

————————————

+3% Veegum T

+13% Bone Ash

Bacterial Cellulose is a material that requires nurture and care. Mothering until death, and still caring afterwards.

Mom, I love you is a project that came from accident. The porcelain piece inside is my favorite thing I have ever (in my entire life) made. It’s a small object, the size of a worry stone or pet rock. It’s silky smooth with bits of glaze and speckles of steel from accidentally introducing it to the metal shop. I have been thinking a lot about what it means to love someone or something. The ceramics was a coincidental piece, serendipitous. It was not planned (the form that is). I don’t know if I can take credit for it because my hands moved on their own accord, possessed when I was thinking of my mom and how much I love her. Even when we fight, even when we cry, even when it its hard. And even when I am scared. Afraid to love her to much, love her to hard knowing that she will eventually die. To hold her to tight, to hug her to tight, to accidentally crack a rib. To love a teacup that will inevitably crack.

But she is not a teacup or any other possession. She is not fragile. She is as resilient as the bricks that built New York City. My mom and I might fight, bicker, piss each other off. The opposite of love is not hate its indifference. And I can’t ever feel indifferent towards her. And I must remind myself, that to miss her is to remember how much I love her.

And to love her is special, it is a secret known only between her and I. Sacred, she is my only mom and I her only child.

So mom, I just wanna say, I just wanted to call to tell you how much I love you.

Process

- Grow Bacterial Cellulose. (To get a thick and juicy Pelical it may take a couple of weeks.)

- Make the media for the cellulose to eat and grow on top of.

- Autoclave the media and make sure that all tools used are sterile.

- Inoculate media with cultures

- Attach nozzles to the bin you are using to grow your cellulose to allow air to enter. (Your bacteria will suffocate without air)

2. When your Bacterial Cellulose is at its desired density (size) its time to kill it.

Day 1: H2O wash and soak. Remove B.C. From the bin it was growing in and wash it thoroughly with water. Use your hands. Leave it soaking in a clean bin with filtered water overnight. (Enough to submerge it completely.)

Day 2: Replace H2O.

Day 3: NaOH soak. This bleaches the B.C. Essentially killing it. NaOH is diluted with water. 9:1 (water to NaOH) or 90% water + 10% NaOH. Use PPE when handling NaOH

Day 4: Stir.

Day 5: Remove B.C. From NaOH soak. Wear PPE. Dump NaOH into a waste bin. DO NOT pour it down the drain. Place B.C. Back into the bin and add H2O.

Day 6: Replace H2O.

Day 7: Harvest B.C.

3. Time to dry out!

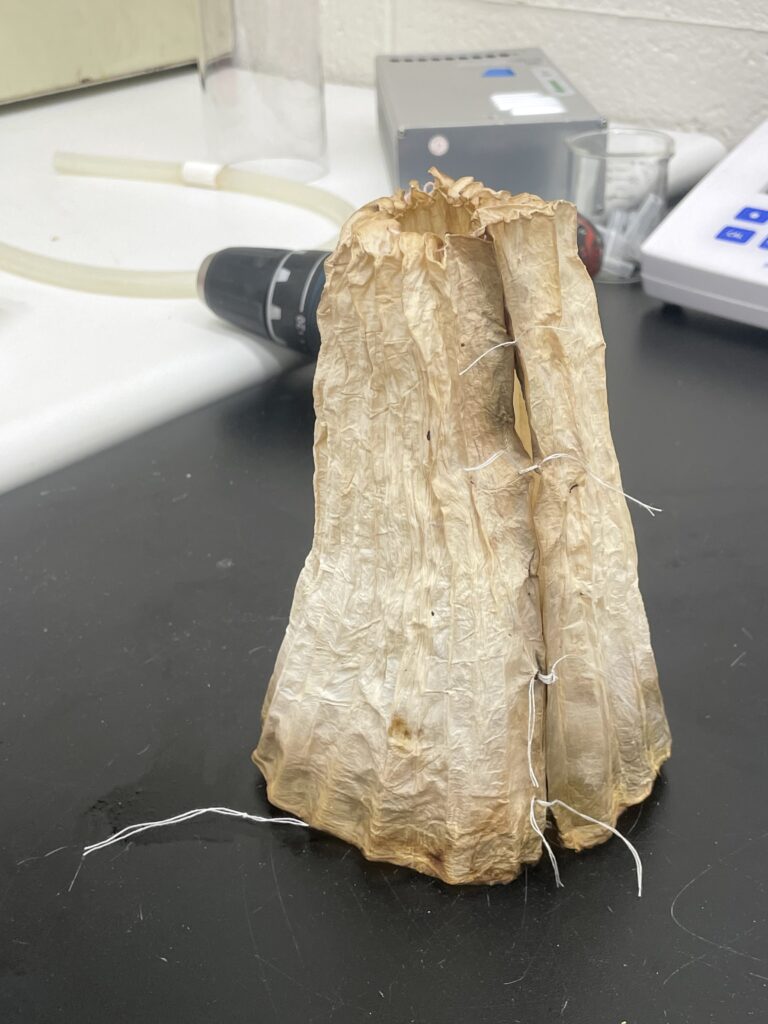

1. I made a laser cut stencil (chipboard) of a pleated lamp shade. I used this stencil to pleat the B.C.

2. I dried the B.C. On the stencil.

3. I further shaped it and stitched the B.C. With thread to hold it in place.

Things I would do differently:

I would cover the stencil with wax paper instead of placing it directly on the B.C. Placing it directly made the B.C. Less translucent because fibers from the chipboard stuck to the B.C.

I would also dry out the B.C more before working with it, get it closer to paper. When I began folding it the material was still to wet which caused me to struggle and warp the B.C.

I would also take in to consideration that thread may not be needed since the B.C. Has the ability to adhere to itself if set when still damp.

Learn More

to be updated 🙂